Avoiding Delays in Construction: Using Hubble to Identify Critical Paths and Synchronize Schedules

Impact of Delays in Construction Projects

In the construction industry, where complexity is the norm, it is unfortunately all too common for projects to experience delays. A study has found that 22% of construction projects were delivered 250 days later than planned, with 13% seeing a delay of at least one year. Such delays can have an impact on the budget, schedule and success of the project, however, the use of the right tools and strategies can help to mitigate the problem. In this article, we look at how Hubble can be used to identify and synchronise the critical paths, and ultimately, how it can help to prevent delays in construction projects.

What Causes Construction Delays and How to Identify Them

Project delays are commonly attributed to mismanagement, which can be circumvented with better visibility into the development. By observing potential issues and recognising potential solutions, construction personnel can identify and counteract disruptions that arise. To achieve this, Hubble offers solutions to maintain project momentum and combat delays.

Using Hubble to Track Progress and Identify Critical Paths

Identify critical paths and potential bottlenecks

In order to ensure efficient project management and avoid delays, it is crucial to identify potential bottlenecks and follow a set of critical paths that will help synchronise schedules. These paths include documentation, fabrication, workforce, safety, and quality operational processes which are unify on a single Hubble Platform consisting of the following systems;

- Hubble Document Management System manages the storage, transmittal, submittal and approval of documents by serving as a centralised file repository with document version control and audit trail.

- Hubble Fabrication Management System manages your entire project timeline and fabrication management flow from production to inspection to delivery tracking and installation monitoring.

- Hubble Workforce Management System manages your worker’s performance, location tracking, time attendance and overtime hours accurately.

- Hubble Safety Management System manages permit to work, toolbox meeting, safety inspection, equipment inspection, safety incident management, safety timeout and safety audit processes.

- Hubble Quality Management System manages your quality inspection checks and defects management.

By following these critical paths, construction projects can be completed on time and to the highest standards, ensuring a successful outcome for all involved.

Track the process in real-time and achieve deliveries that are just in time

Hubble's Fabrication Management System allows project managers to track the entire fabrication delivery process in real-time, streamlining communication and coordination between stakeholders in the construction chain, from precast suppliers in the upstream chain to contractors in the downstream chain. This leads to the following benefits:

- Efficient component tracking, reducing man hours and surplus components

- Simplified logistics, avoiding storage fees and overordering

- Reduced material management costs by ensuring the right components are available at the right time and place

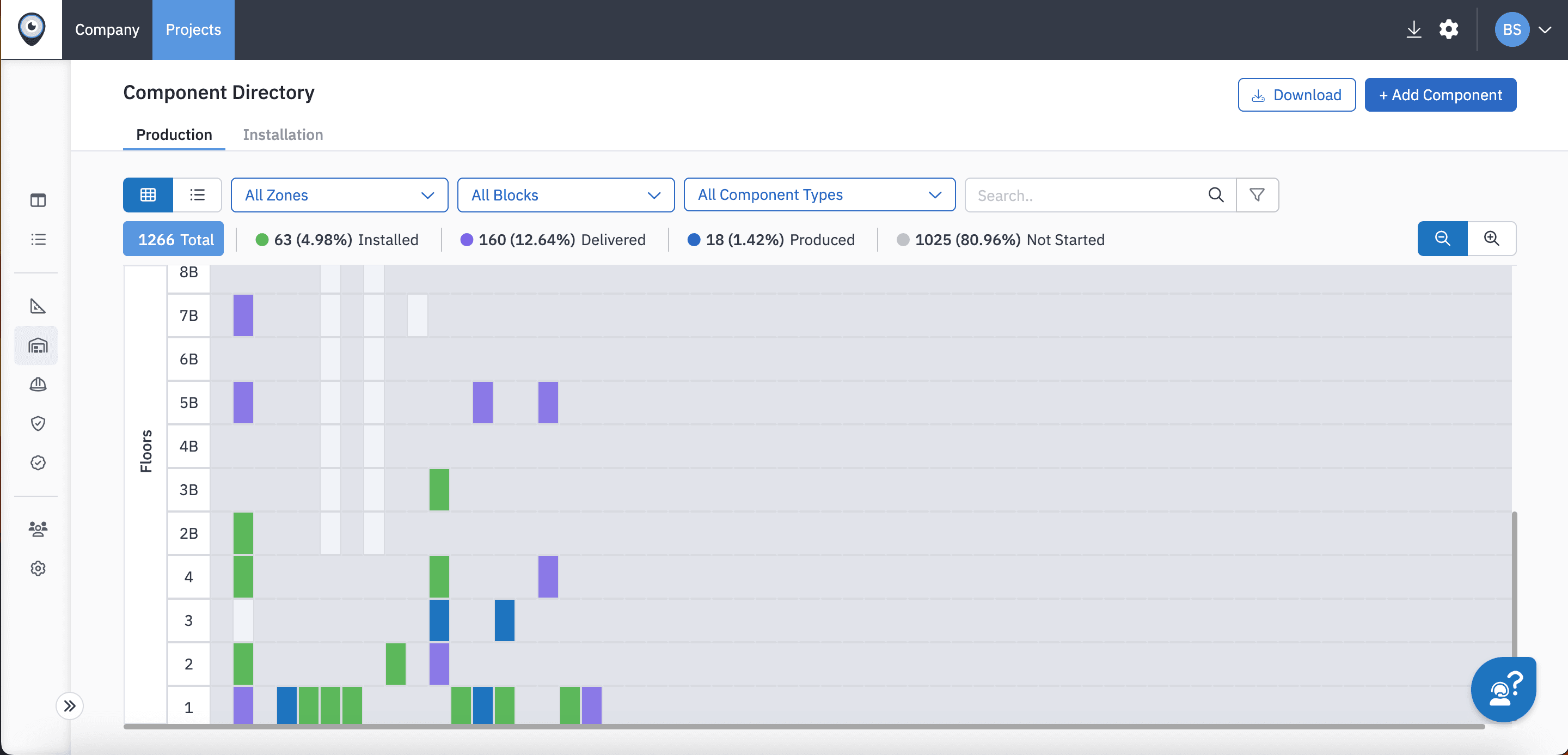

Image: Colour-coded statuses for production in Hubble Fabrication Management System

Monitor and manage projects’ and contractors’ performances

Stay ahead and never miss any pending issues with Hubble Dashboard that helps you track progress in real time and identify potential critical issues in construction projects to avoid delays. It provides insights into safety and quality processes, such as Permit to Work approvals, toolbox meetings, safety inspections, and quality management. The dashboard alerts project managers of bottlenecks in the approval process, unrectified safety issues, and commonly occurring work defects, allowing them to monitor progress, resolve issues, and remove roadblocks in the construction process. The reporting offered by the dashboard helps managers pinpoint the source of delays, eliminating the need to comb through the workflow endlessly.

Image: Dashboard overview of Hubble Safety Management System

Real-World Examples: How Companies Have Used Hubble to Avoid Delays

Hubble has been used by many construction companies to avoid delays and improve project management. Watch how our clients have succeeded with us through our customer stories.

Synchronising Schedules Across Multiple Teams and Worksites

Coordinating multiple teams working on distinct elements of a construction project at various locations can be challenging. Fortunately, Hubble provides a solution. It facilitates sharing critical schedules across teams to ensure they are all focused on the same time frame. Plus, Hubble allows managers to allocate tasks to particular team members, providing everyone clarity on their duties and permitting better preparation of their daily tasks.

Additional Tips and Best Practices for Mitigating Construction Delays with Hubble

Share important schedules across different teams

Utilising the Followers feature in Hubble, communication and collaboration has been made easier. Detailed reports, ready to share, are compiled into PDF documents, making them convenient to send and comprehend. Notifications, set up automatically, advise the right people on any changes and help keep everybody in the loop. Workflows become quicker and better with the capacity to include followers and keep them updated on important information in real-time.

Assign tasks to multiple team members

Assigning tasks to multiple team members simultaneously can enhance flexibility and collaboration, ultimately leading to more efficient task completion. This approach enables the team to work collaboratively and utilise their strengths, maximising productivity and output. By leveraging the collective expertise and knowledge of the team, projects can be completed more quickly and effectively, improving overall performance and outcomes.

Image: Assignees and followers function in Hubble when creating a case

Communicate effectively with all team members

With automation of scheduling and tracking, Hubble gives you real-time insights to optimise your workforce management and streamline your processes. The system makes it easy to attach photos of defects to a digital floor plan and indicate their location, allowing for better precision during inspections and reducing communication errors. Additionally, the ability to add annotations to defect and inspection photos, along with the support for floor plan zoning, further improves inspection accuracy and helps to prevent mistakes.

How to Keep Your Construction Projects on Schedule with Hubble

Keeping construction projects on track can be a difficult task due to their complexity and multiple facets, yet, it is possible with the correct tools and tactics. By leveraging Hubble to observe development, discern significant paths, and organise schedules, construction pros can stop setbacks and guarantee their initiatives are done on schedule and within budget. If you'd like to learn more about how Hubble can help you streamline your construction projects, reach out to us today.

Share this article

Explore Related Content

Stay up to date with our latest news features!